Opalux exterior clear safety films are available in 100micron or 175 micron thickness and are specially manufactured to withstand the elements.

They are used where both interior and exterior films have been specified for application to both sides of the glazing units for extra strength and protection. This could be for any number of reasons to provide a double protection safety or security application.

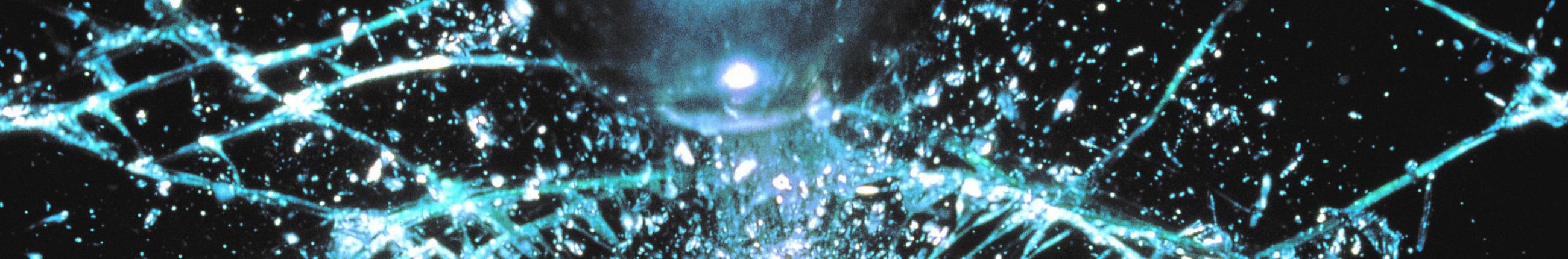

A regular use of these exterior films is to hold glass together where there is a history of spontaneous shattering of glazing units in overhead or vertical situations creating a severe and unpredictable risk to the public. This happens where the glass has been weakened due to hidden imperfections caused by faults such as nickel sulphide poisoning occuring during the manufacturing process.

An application of interior or exterior safety film, often backed up with a retention system (see side menu) to hold the glass panels in their frames, has been the cost-effective safety measure to avoid the high cost and disruption of replacement of all the glazing units.

Another use of exterior safety film is in regulation 14 contracts where the inside surface of the glass is too patterned to take film and the outside surface is smooth. If both surfaces are too patterned then a Decothane treatment from Liquid Plastics may be acceptable rather than reglazing.

Accurate selection of film requires specialist knowledge and end-users and specifiers are encouraged to consult Opalux technical department.

Where appropriate you will be connected to an Opalux approved dealer who can discuss your requirements, visit site if necessary, and provide costings for the film installation.